Facilities

Our group uses the following facilities on SFU Burnaby campus, BC:

Fabrication equipment:

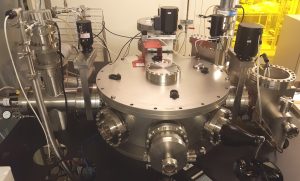

- Multi-chamber cluster deposition tool consisting of plasma-enhanced chemical vapor deposition (PECVD), magnetron sputtering chamber, high temperature evaporation, and atomic layer deposition (ALD).

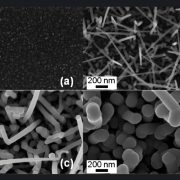

- Chemical Vapor Deposition system for large area MoS2 synthesis.

- Hydrothermal Reactor for 2D tellurium synthesis.

Material and Device characterization:

- Transient photoluminescence.

- Transmission, Reflectance, Absorption using an integrated sphere in the visible (300-1100nm) and infrared regions (900-1700nm).

- Temperature controlled probing stage.

- Solar simulator (AM1.5 Global) and External Quantum Efficiency measurements.

- Volatile organic compound and inorganic gas testing system.

- Fume hoods for sensor functionalization.

- Probe Station.

Engineering Science Cleanroom shared facilities:

- mask aligners for photolithography

- reactive ion etch (RIE)

- wet etch processes (fume hood)

- deep reactive ion etch (DRIE)

- XeF2 etch

- Dektak thickness profiler

- four point probe

- Atomic Force Microscope.

A variety of fabrication and characterization equipment is also available at SFU’s 4DLABs (www.4dlabs.ca).